Disclaimer: This post may contain affiliate links, meaning we get a small commission if you make a purchase through our links, at no cost to you. For more information, please visit our Disclaimer Page.

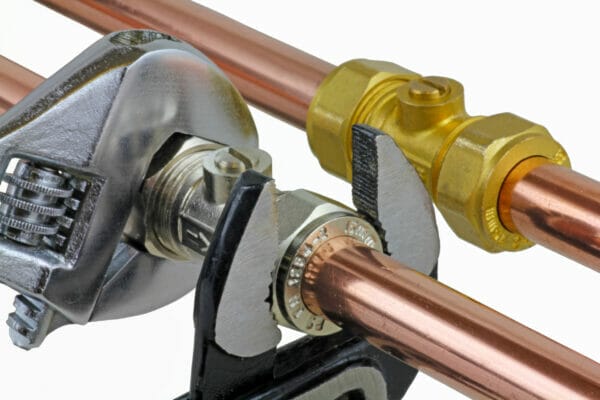

A hand-tight fit is perfect for any gas compression fitting. This results from the soft copper olive rings in the fitting that make it easier to hand tighten, sealing the joint. Gas leaks are nonetheless susceptible in these joints due to over-tightening the nuts, squeezing the copper olives.

Table of Contents

Are Compression Fittings OK for Gas?

Compression fittings are not ideal for gas pipelines even though they offer performance advantages. They are quite complex and must be handled with extreme care by professionals in the gas industry only.

The fittings, however, perform better when used with wet pipes. This provides a superlative seal that is unachievable by other fittings, including soldering.

This whole system has a lot of sensitivity because of the copper olives, threaded fittings, and hefty coupling nuts. If not tightened properly, the nuts can over-compress the copper olives, resulting in gas leaks.

Additionally, while it is possible to use these joints for gas pipe connections, these joints are not 100 percent efficient.

It is, therefore, necessary to consider both their advantages and disadvantages before relying heavily on them for gas connections, aside from the fact that professionals must supervise them.

Advantages of Compression Fittings in Relation to Gas Connections

Eliminates the Need for Soldering

Except for fuel gases, which you should not solder to their fittings, gas pipes have no relative effects with soldering.

As a result, gas compression fittings are important when technicians lack jointing means due to the complexity of the joints.

Quick and Easy Fix

The operation of compression fittings is more manual fit since they require no special tools for their operation. This is because the copper olives need hand tightening to prevent any damage they may sustain.

Useful for Heat-free Connections

Gas pipes sometimes contain flammable gases, so they would explode if heat or torches were used to repair them. The compressed fittings are therefore useful.

- The ease of handling makes compression fittings ideal for joints or sections that require occasional fixing.

- Although disassembling the joints requires cutting the already compressed copper olives, it is not as time-consuming as it would have been if you were to use specialized tools to unscrew the nut.

Even though compression fittings have many advantages, they are quite sensitive to powerful stress and any pressure surges that may occur in the gas connection, which may cause leaks. Additionally, they must be flat on the surface despite their unattractive appearance for easy monitoring.

So generally unless assessed and approved by relative authorities, gas compressed fittings should not be used because of the complexity that comes with their installations.

The nuts, the bulky weights in the joints as well as their need for minimal pressure could trigger disaster anytime.

How Tight Should a Gas Compression Fitting be?

Gas compression fittings do not use jointing compounds in their connections. Instead, they use soft copper olive rings.

So they can only be hand-tightened to the fitting because these rings are very soft, so any tools used during the closure of the same could cause leakage of the contents of the tubings.

Generally, a sealant is a good way to ensure no leaks, but in compression fittings, its use will prevent the copper ring from entangling properly with the fittings. As a result, you have an outstanding joint with an olive ring as the sealant.

What Are the Different Types of Compression Fittings?

Brass, plastic, cast iron, and copper are among the useful materials in the making of compression fittings.

However, their applications vary depending on the materials and contents in transit. For example, copper compressed fittings are the best choice for gas pipes.

These fittings are available in two general types, they are:

Non –manipulative Fitting

These are very easy to install and do not require modifications at all. In addition, they are unique for using olive rings that are secured with nuts, making them ideal for use in water pipes.

Manipulative fittings

These are a bit different because they require a wrench or other specialized tool important for tightening the coupling nut, making them effective for high-pressure contents.

Installation Guides for Compression Fittings

- You should not use gas compression fittings on bent tubings or pipes.

- Do not over-tighten the coupling nuts during installation because there is a point beyond which they achieve no effect.

- Avoid using compression fittings with non-flexible connections. It is always a good idea to pair them with stationary or permanent fittings. To keep them in place, these fittings need to be able to restrict any movement of the pipes.

How Do I Know If My Compression Fitting is Tight Enough?

During installation, you should slide the nut over the fitting ring and thread it until it is hand-tight.

When you follow the thread of the coupling nut closely, you can tell if the ring is tight, but only when you do not cross-thread; it is obvious when you can spot the last fraction of the thread on the fittings.

In the event that you are not happy with the fitting, you can fit a wrench to its body and hold it tight to prevent it from moving. Next, tighten the compression nut using another wrench for not more than a half-turn; the maximum is three-quarter turns.

Also, remember that overtightening the nut can cause damage to the soft copper olive ring.

How Long Do Compression Fittings Last?

Compression fittings differ from threaded fittings in that, you can easily tell their seal by how well the nut grips the fitting without overcompressing the soft copper olive.

Despite their versatility, their longevity remains dependent upon their current application, even though most technicians consider them to be more reliable.

Additionally, compression fittings are not as vibration-resistant as threaded fittings. Due to this, they often limit their applications to only contents that would not pose a high risk if a little damage occurs on the joints.

Typically, they are useful in applications in which there will not be bending or flexing of the gas pipes. The compressed fitting in such an application is sensitive to any relative dynamic stress, and as a result, it has no guaranteed lifespan.

In addition to their uncertain lifespan, these fittings tend to be bulky with poor aesthetics, and are easily deformed.

This discourages people from using them for their needs. As part of their irreversible process, if you are ever required to undo the compressed fitting you will need to remove the soft copper olive and replace it with a new, non-compressed olive.

While other tool tightened fittings will need specialized tools to unwind the coupling nuts.

Taking this step ensures a leak-proof connection at the next connection.

What are the Most Common Causes of Leaks in Compression Fittings?

You need to use compression fittings with utmost caution in their applications. Because of this, most gas applications utilizing these fittings require approval from the relevant regulatory authorities.

As a result, you need to straighten any pipe feeding these fittings into place, since any misalignment may cause a leak.

The use of any joint compound limits the effectiveness of the copper olives as well as posing the possibility of a leak through the joints.

It is therefore essential that any user applying the compression fittings in their work checks the joint for leaks.

The possibility of a leak is locally determined by using soap and water on the joint parts. Any bubbles detected will indicate the presence of a leak.

It is undesirable in such instances; however, because the entire compressed olive should be removed before a new one can be installed that would not compromise the joint’s functioning.

Conclusion

Therefore, despite some of their varying advantages, gas-compressed fittings can only be a hand-tight fit to prevent any possible leaks. Over tightening, the nut to the fittings exerts excess pressure on the soft copper olives leaves minute spaces through which gases escape during transit.