Disclaimer: This post may contain affiliate links, meaning we get a small commission if you make a purchase through our links, at no cost to you. For more information, please visit our Disclaimer Page.

Pipe coating can double the lifespan of pipes. A standard pipe in optimal conditions and constant maintenance can last for 30 to 50 years, and a coated pipe in the same conditions can last over 60 years depending on the type of coating process they had.

Table of Contents

Is Pipe Coating Worth It?

Pipe coating is a method to protect the pipe structure against corrosion and other elements that can damage the pipeline over time. Nowadays, this is commonly used by companies to make the pipes last more, and this also adds more value to the pipes, so the cost of these increases.

Pipe coating will improve the overall performance of the pipeline; thus, this may not seem obvious in the beginning, but through the year, the pipes will maintain their integrity so do their quality. Moreover, coated pipes will deliver a cleaner product since the corrosion of the pipeline will be minimal, and consequently, the maintenance of the pipe is low-cost and less frequent.

A coated pipe is a good inversion. These pipes will last more than other pipes because they have extra protection against external corrosion that also adds minimal protection to the inside of the pipe.

Thus, a coated pipe doesn’t need to be replaced often because of its durability, and this also reduces the maintenance cost.

Therefore, pipe coating will reduce the overall cost, including energy and product cleaning; the product that goes through the pipe will reach its destination cleaner and faster than it is expected.

Acquiring a coated pipe is worth it, and if you are on the seller and manufacture side, pipe coating will add extra value to the product!

Pros and Cons of Pipe Coating

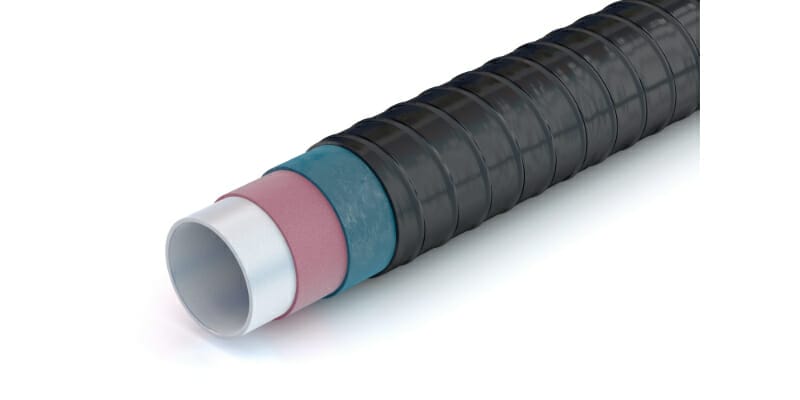

Pipe coating has more advantages than disadvantages. In general terms, pipe coating is a method that adds extra protection to the pipeline; thus, the coating is doing on the outside, inside, or on both sides giving it more strength to the pipe.

However, the pipe coating has to be applied carefully because a wrong procedure can damage the pipe.

Though not all the coatings are done similarly; the materials and techniques used in the process can change according to the countries standards and companies, but there are some very famous around the world: Coal tar Enamel, Metallic Spray, Epoxy Coating, Polyolefin with Butyl Adhesive Coating, Dual Coating, and Multi-layer Systems.

Some coating processes have become controversial because of their high toxicity, side effects, and even some coatings are dangerous for human health.

Then, as much as some can be a risk for humans, they are also dangerous for the environment, and it is not only the materials used but the coating process itself.

A few coating processes can leave toxic chemicals that affect animals and their habitats.

How Long Does Pipe Coating Last?

Pipe coating is used to extend the life of the pipe; though, the overall durability of the coated pipelines will vary according to the coating process that they were put through.

However, a standard pipe can last for 30 to 50 years with proper maintenance in optimal conditions, and a coated pipe in the same conditions can last over 60 years depending on the type of coating process they had.

The durability of the pipelines depends on the materials these are made, and the coating process they went through.

Nowadays, the coating process can change according to the country standards, the type of project, and the companies themselves; epoxy resin-coated pipes tend to last more than other types of coating.

Also, the multi-layer or duo systems last more than the average coating methods.

But before starting the coating process, all the pipes receive a cleaning process. The cleaning process is more extensive for those used pipes.

The final mission of coatings is to give protection against corrosion, and the used pipelines have a cover of corrosion and dirt in the inside and outside of their structure; this cover is removed, and the pipe surface is smoothed.

After the cleaning stage, some pipes receive preheating treatment before the coating process.

The curing process is also different depending on the coating process, so I’m going to clarify more about the most used coating methods and how these are done to understand more how these can last over the years.

Coal Tar Enamel (CTE)

Coal Tar Enamel is the service most used in the industry of pipe coating. This company has been working for over a century and has its patented coating process.

The coating covers of CTE protect pipelines against natural elements that cause corrosion, such as extreme temperatures, acids, salts, and moisture.

The Coal Tar Enamel has developed waterproof and film-forming properties that place the company over many that use similar coating methods. Thus, the company is constantly searching for materials that increase the durability of their coatings; this upgrades the overall value of their services, but the results can be worthwhile.

The coatings made by the CTE last more than the average, but in certain conditions, the CTE coatings can suffer from stress crack corrosion.

Metal Spray for Pipe Coating

Metal Spray for pipe coating is a fast solution that doesn’t require any previous experience. Using metal spray in pipe coating will extend the life of the pipeline for over 5 to10 years; though some people think this is not too much, metal sprays don’t need an extensive application or curing process.

For the application process, apply the spray over the pipe surface, and then let it rest until it dries; some people recommend letting it rest for a day.

Metal Sprays for pipe coating come in different presentations, and they can be bought in hardware stores. The disadvantages of metal sprays are the low durability and protection these give to the pipes.

The sprays are a solution for amateurs or those who want to enhance the performance of the pipes at their homes.

Fusion Bonded Epoxy Coating

Fusion Bonded Epoxy Coating or FBE Coating is a thermoset coating. Here, the coating process is done by using a resin (in this case, epoxy resin); then, the pipelines go through a curing process where it uses heat or radiation to solidify the resin.

Additionally, in this coating process, the epoxy is a powder that is later melted in 200 to 250 °C.

The melted epoxy makes a film that covers the surface of the pipes, and it is cured using chemical cross-linking and heat.

This FBE coating process made the pipelines highly resistant to corrosion, raising their lifespan for over 10 to 15 years.

Three Layer Polyolefin Coating

Three Layer Polyolefin Coating is widely used all over the world. This polyolefin coating gives the pipeline a high resistance against corrosion but in the short term.

The polyolefin layer has poor adhesion to metals, and the coating tends to peel easily from the pipelines after a few years.

However, the polyolefin coatings became famous because of their great resistance to high temperatures and eco-friendly properties.

Thus, this type of coating is mostly used for electrical pipes because of its general properties. But, since the Three Layer Polyolefin coating has poor adhesion, this doesn’t last enough and hardly increases the lifespan of the pipes.

Multi-Layer and Duo Systems

Multi-layer systems add a considerable lifespan to the pipe, mostly if these are made of epoxy resin. However, the curing process is more extensive than single-layer systems.

And the Dou systems involve coatings inside and outside the pipes, so ꟷsimilarly to multi-layer systems,ꟷ the curing process takes longer than usual.

These systems add more durability and higher corrosion protection to the pipelines, so, tend to last more than standard coating methods.

How Much Does Pipe Coating Cost?

The cost of pipe coatings can vary according to the type of coating, the pipe condition, and the cleaning process.

The overall condition of the pipes can vary; some pipes aren’t new, so they need an intensive cleaning before applying the coatings; thus, another essential factor to consider is the size of the pipelines.

Anyways, many companies offer pipe coating services, but if someone wants to do it by themselves the pipe coating can find epoxy paints for around 2 to 10 dollars in hardware stores.

Conclusion

Pipe coating adds extra protection to the pipelines so these can endure damages over the years, but it’s essential to find an accurate coating for the pipe.

The coatings can add strength to the pipes, extend their lifespan for a few years, and protect them against corrosion.

References

https://www.usbr.gov/research/projects/download_product.cfm?id=2651