Disclaimer: This post may contain affiliate links, meaning we get a small commission if you make a purchase through our links, at no cost to you. For more information, please visit our Disclaimer Page.

Compression fitting leaks most often occur from overtightening. It is imperative not to overtighten the nut to avoid damaging the compression fitting. A ferrule that is too tightly tightened will deform improperly, resulting in the joint failing.

Table of Contents

Why Do Compression Fittings Always Leak?

A leaky compression fitting can also be caused by overtightening it. When tightening a compression fitting, only tighten it until it feels resistant. It is a good idea to only postulate a half-turn from there. As a result, your compression fitting will be safe from leaks.

Working of Compression Fitting

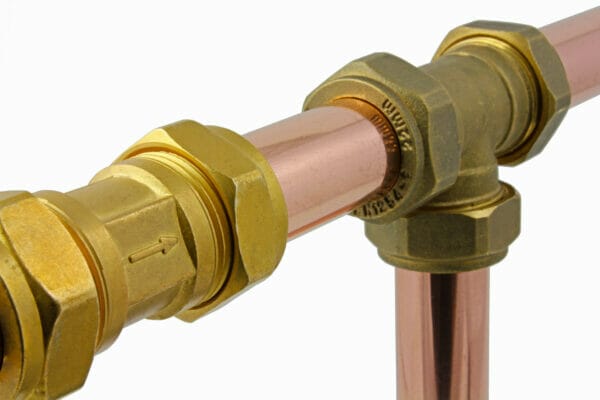

The outer compression ring or ferrule is usually brass or steel for small-size compression fittings, while the inner compression ring is usually aluminum.

Most commonly, ferrules are in the form of beveled rings in various shapes and materials. You should keep the ferrule oriented for it to work properly. Copper olives are normally cylindrical, which means they cannot be installed incorrectly.

However, where this is not the case, particularly those used in hydraulic and high-pressure applications, the ferrules are fitted so that the sloping touches the nut at an angle.

It is during this compression that the ferrule between the nut and the receiving fitting is compressed. The middle of the ferrule is supposed to bow away from the pipe when clamping a barrel-shaped copper olive around it.

Consequently, both ends of the copper olive are clamped around the pipe. The bolt ring on larger compression fittings performs the compression function instead of a single nut on smaller fittings.

You must distribute a bolt’s torque. You do not require using joint compound on the fitting threads. The reason is that instead of the thread, the ferrule seals the joint between the nut and pipe.

The threads can be lubricated with plumber’s grease or light oil, helping to ensure a smooth, uniform tightening of the nut. It is imperative not to overtighten the nut to avoid damaging the compression fitting.

Overtightening the nut will cause the ferrule to deform improperly, resulting in the joint failing. Often, leaks in compression fittings are caused by overtightening.

To tighten a nut, tighten it first by hand until it becomes impossible and then tighten it one half-turn more with a wrench; the amount will vary according to the size of the fitting since a larger one will require less tightening.

It is then tightened gradually until no more weeping occurs. By its very nature, compression fittings are prone to ferrule damage. Thus, the ferrule should be handled with care and tightened if it is damaged.

What Is the Most Common Cause of Leaking Compression Fittings?

In addition to being inconvenient, you can repair leaking compression fittings sooner to avoid unnecessary loss. If you do not know about compression fittings, they are small devices used to join pipes or connect pipes to fixtures.

There are three prime parts of compression fitting: the compression ring and nut and the compression seat. Wearing these pieces out, breaking them, or not putting them on may result in leakage.

Compression fittings may leak for several different reasons. I want to start with improper use. The following tips will help you. Using compression fittings should be limited to stationary connections.

The pipe connected to compression fittings cannot move back and forth due to their tightness. For the pipe to remain stationary, you must fix it. Compression fittings could leak if they are bent back and forth constantly.

In addition, unless you plan on using it underneath the kitchen sink, you should avoid using double compression fittings. It is because that there is very little movement and stress.

A solder or heat-sweeping connection would be better if there is any movement or stress. In addition to overtightening, compression fittings can leak if they are overtightened.

You should only tighten the compression fitting until the tool feels resistant. It is a good idea to only postulate a half-turn from there. As a result, you can prevent leaks in compression fittings.

How Do I Stop My Compression Fitting from Leaking?

To fix a leak in your copper compression pipe, try loosening the nut and retightening it first. Plumbing professionals use this trick everywhere.

If you loosen up the nut and retighten it, you also remove corrosion from the nut’s threads, which sometimes stops the leaking. As a result of this corrosion being removed, the compression nut can be tightened even more.

Consequently, the seal will be tighter. Make sure to close your inlet valve before you begin. It will shut off the water supply. You can end up with a wet mess if you don’t do this.

You can lay down a dry towel or bucket to catch any water that leaks out while you loosen the nut. If your compression fitting still leaks even after tightening the nut, turn on the water again. In that case, you should probably replace it.

Replacing the Compression Fitting

Shut off your water again by closing your inlet valve before installing your compression fitting. You can start removing the old compression fitting once you have turned off the water.

The male end of the compression fitting should be grasped and held firmly with standard pliers. As you rotate the compression nut counterclockwise, be careful to keep it steady with another pair of pliers.

If you have already loosened the nut, unscrew it completely by hand after it has become loose. Hold on to the compression ring, also called the ferrule, using a pair of pliers.

You can loosen it by turning it with the pliers. Remove it once it has become loose. Occasionally, cutting the nut off won’t be easy, and sometimes you have to remove it by hand.

You will need a hacksaw in this case. The hacksaw will help you to remove the pipe. When cutting the nut, you need to get as close as possible to the back. You need to fill the pipe end after removing the nut until it is smooth, after which you need to reinstall the nut.

As a next step, you will need to remove the compression nut from the end of the pipe and slide on the new nut, ring, and seat into place. Then make the water on and compress everything up.

It’s critical to note that reusing your old compression nuts is not recommended. Because the nut is so difficult to remove, some people choose to reuse them. Leakage is likely to occur if you reuse an old nut.

Make sure a new one is used to avoid this problem. By doing so, leakage is prevented. When replacing your compression fitting, you may also want to use either a plumber’s grease or pipe dope.

You will not only be able to tighten your compression nut, but you can improve the seal. The pipe can always be frozen with the compression fitting replaced if you cannot turn off the water source.

In today’s market, aerosols and electrical kits are available in large numbers to help you fix the concern. In these products, a coolant is used to freeze both the pipe and its contents rapidly.

It’s unnecessary to turn off the water when replacing the compression fitting if the pipes are frozen. You should follow the directions carefully when you utilize any of these products. Eliminating unnecessary problems will be easier this way.

Conclusion

Overtightening the compression fitting is usually the prime cause of leakage. If you do not want your compression fitting to leak, then avoid overtightening. Overtightening the compression fitting will minimize its strength due to excessive force.

However, if you are dealing with leakage compression fitting, then go through this article as you will surely find various solutions to fix it. You will learn to fix the compression fitting via this article.